Steel is not just a combination of iron and carbon. It comprises different grades and thus it has versatile applications. Made as industrial grade alloy steel bars they add weight in the manufacturing process. With the amount of carbon measurement, the steel grade can be identified. According to authorized sources of grades the steel types come in 4 groups. They pertain to carbon, alloy, stainless steel and tools.

This blog post offers an insight into the company’s diverse portfolio of products related to Alloy Steel Round Bars.

Alloy steel basics

Alloy steel is blended with other elements to augment the inherent properties of the raw material. Other materials like vanadium, copper, magnesium, cobalt, aluminum cerium, niobium, titanium, tungsten, tin, zinc, lead, and zirconium areadded in a ratio of 1 wt.% to 50 wt.%. When these elements are added they increase the ductility, strength resistance and machinability. The industrial grades are created depending on the core applications to distinguish the need of each product. For instance, the strength is determined when the steel is cooled at a molecular level. This is why two sheets of steel with the same alloy to be graded differently: The heat treatment plays an essential role.

Grading system

The grading system is usually of interest to the engineers, scientists, government agencies and even architects. They check for consistency and reliability of the materials.

ASTMGrade: Each metal has a letter pre-fixed based on the category. For example, ‘A’ is for iron and steel materials. Another number is assigned to depict the corresponding metal properties.

SAE grade: A 4-digit method is used for its classification. The first two digits refer to the steel type and element concentration of the alloy. The other two digits refer to the carbon content in the metal.

The classifications ensure that the consumer is able to understand the quality of steel with the specifications and guidance that manufacturers need to take care of.

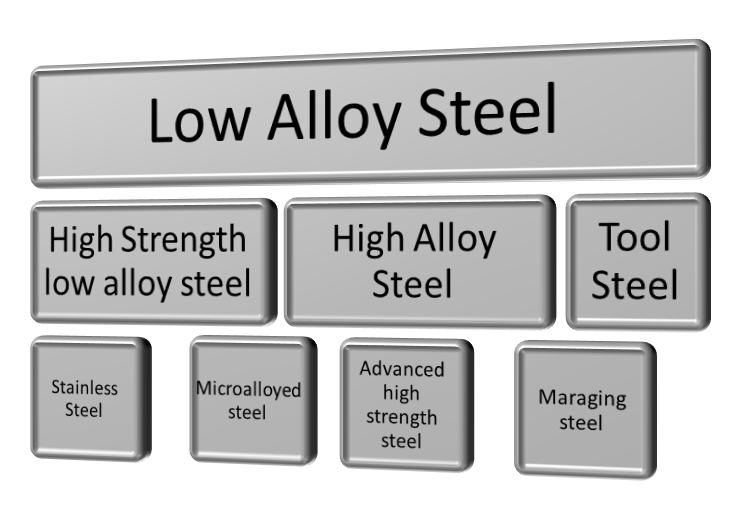

Types of Alloy steel

Alloy steel round bars made by Nilesh Steel company are designed to meet all the statutory compliances. Hence, customers are supplied with the best products. You can order the following from our product line for any industrial application. We ensure the suitability of the product and the industry standards.

- 30CRNIMO8 ROUND BARS

- 34CRNIMO6 ROUND BARS

- 39NICRMO3 ROUND BARS

- SAE/AISI 4130 ROUND BARS

- 25CRM04 ROUND BARS

- EN26 ROUND BARS

- EN30B ROUND BARS

- EN39B ROUND BARS

- EN25 ROUND BARS

- 30CRMOV9 ROUND BARS

- EN40B ROUND BARS

- SAE/AISI 4340 ROUND BARS

Best Applications

There are plenty of applications and uses for alloy steel round bars. For instance, the low steel alloy products have a great strength value. They are cost-effective and ideal for their common availability. Ship building, pipelines, Military vehicles, oil drilling platforms, construction equipment, pressure vessels and various structural components derive their durability from this alloy steel.

In comparison to the above, high-alloy steels are expensive and also the manufacturing process is complex. But the end product is hard, corrosion resistant and tough. It is used in sectors like automobiles, power generation and chemical processing.

Nilesh Steel Company is a well established manufacturersupplying a variety of industrial grade alloy steel round bars. We have set a good quality standard to help our customers to place custom orders with specifications.